Product Introduction:

The horizontal decanter centrifuge is developed and improved by our factory based on introducing foreign advanced technology. It is mainly used in solid and liquid separation of city wastewater, industrial wastewater, chemical, food, pharmaceutical, non metallic minerals and other similar production processes of different fields.

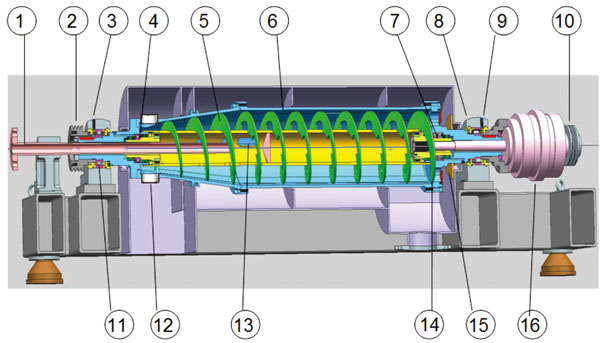

Structure:

1-Feeding pipe;2-Main motor belt pulley;3-Main bearing oil injecting nozzle;4-Bearing of screw;5-Spiral vane;6-Rotary drum;7-Bearing of screw;8-Main bearing;9-Main bearing oil injecting nozzle;10-Secondary motor belt pulley;11- Main bearing;12-Solid discharge;13-Outlet;14-Liquid discharge;15-Liquid baffle;16-Differential;

Specification:

|

Model |

Main technical parameters |

Motor power |

Dimension(mm) |

Total weight(KG)

|

|||||

|

Drum diameter (mm) |

Maximum RPM (rpm) |

Length (mm) |

Maximum separation factor(G) |

Capacity M3/h |

Main motor (KW) |

Secondary motor (KW) |

L×D×H |

||

|

TPLW250×1100 |

250 |

5400 |

1100 |

4080 |

1-5 |

11/18.5 |

7.5/11 |

2380×1400×800 |

1000 |

|

TPLW350×1250 |

350 |

4200 |

1250 |

3450 |

3-10 |

11/18.5 |

7.5/11 |

2650×1200×872 |

2000 |

|

TPLW350×1500 |

350 |

4200 |

1500 |

3450 |

3-12 |

11/18.5 |

7.5/11 |

2913×1300×872 |

2000 |

|

TPLW350×1600 |

350 |

4200 |

1600 |

3450 |

3-12 |

11/18.5 |

7.5/11 |

3000×1500×872 |

2200 |

|

TPLW430×1400 |

430 |

4000 |

1320 |

3845 |

4-25 |

30/37 |

11/15 |

2500×1500×1000 |

2450 |

|

TPLW430×1700 |

430 |

4000 |

1600 |

3845 |

4-28 |

30/37 |

11/15 |

3100×1550×1000 |

2500 |

|

TPLW430×1800 |

430 |

4000 |

1800 |

3845 |

5-32 |

30/37 |

11/15 |

3200×1550×1000 |

2950 |

|

TPLW450×1600 |

450 |

3800 |

1600 |

3632 |

5-30 |

30/37 |

11/18.5 |

3000×1550×1000 |

3100 |

|

TPLW450×1800 |

450 |

3800 |

1800 |

3632 |

5-35 |

30/37 |

11/18.5 |

3200×1550×1000 |

3250 |

|

TPLW500×2000 |

500 |

3500 |

2000 |

3423 |

10-40 |

37/45 |

11/18.5 |

3550×1600×1100 |

3600 |

|

TPLW530×1300 |

530 |

3500 |

2000 |

3630 |

10-45 |

45/55 |

15/18.5 |

3550×1700×1200 |

3800 |

|

TPLW530×2000 |

530 |

3500 |

2200 |

3630 |

10-50 |

45/55 |

15/18.5 |

3800×1700×1200 |

4000 |

|

TPLW550×1300 |

530 |

3500 |

2000 |

3630 |

10-45 |

45/55 |

15/18.5 |

3550×1700×1200 |

3800 |

|

TPLW550×1900 |

550 |

3200 |

1900 |

3630 |

10-50 |

45/55 |

15/18.5 |

3500×1700×1250 |

4200 |

|

TPLW650×2200 |

650 |

2800 |

2400 |

2980 |

15-60 |

55/75 |

15/18.5 |

3800×1800×1300 |

6500 |

|

TPLW800×2200 |

780 |

2500 |

2200 |

2560 |

20-70 |

77/110 |

30/37 |

4000×2000×1500 |

8500 |

Main Features:

1. Good adaptability: All kinds of special requirements of raw material and technique on centrifuge are fully considered in the design. the main function parts are improved in speciality and adjustability. As long as users explain the location of their installation, physical and chemical characteristics and process requirements, we will provide users the most suitable models.

2. High degree of automation

3. Good running stability: The differential used by centrifuge is second-stage involute planetary gear differential, which adopts the unique low oil level operation technology of our factory, with low working temperature, large transmission torque and reliable performance.

4. Strong technique:The centrifuge adopts dual motors, double frequency conversion energy feedback differential speed system, which can realize flexible speed regulation and online intelligent control for differential speed, and adjust differential speed at any time according to the change of material.

5. Corrosion resistance:drum , screw body, hood and other parts contacting with material are made of high quality stainless steel

6. Good operating environment

7. Complete safety protection device: Torque protection, power control, vibration and temperature measurement and other multiple protection.

8. Good appearance