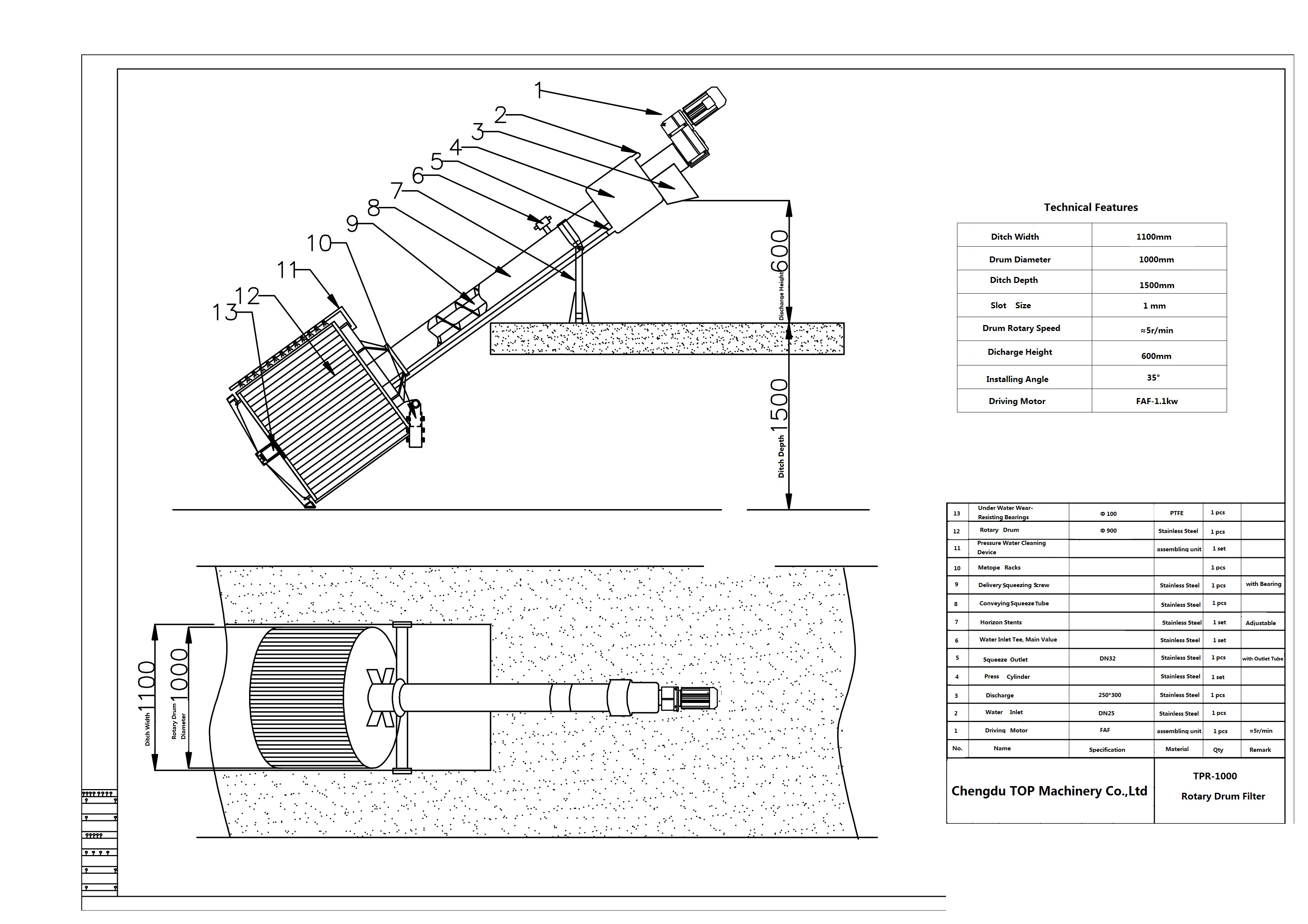

Product Introduction

The TPR Rotary drum screen is widely applied for wastewater treatment projects such as urban wastewater, industry wastewater, food process industry, paper industry and so on. This equipment can clean scum, short fiber and suspended matter from the water intake, and then discharge them after dewatering. It can be used for wastewater treatment engineering such as high precision process, small grid gap and low depth of canal.

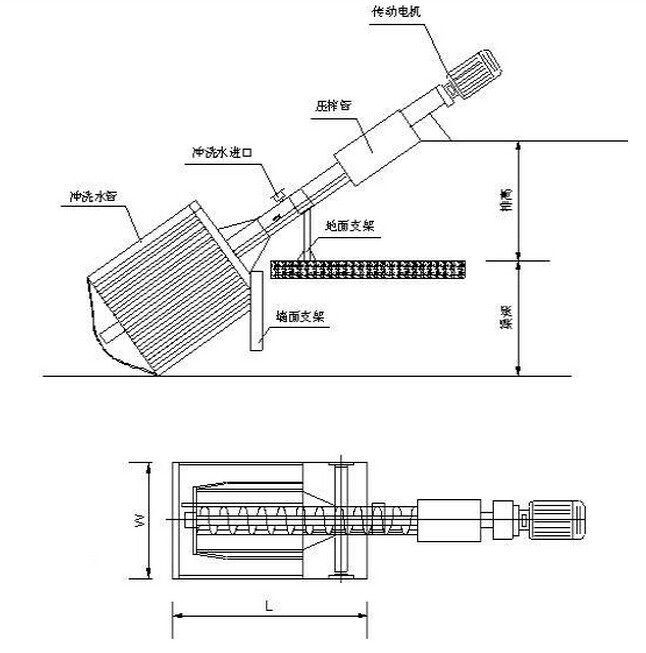

Working Principle

This equipment has four functions such as intercepting dregs, getting rid of dregs, spiral lifting and pressing dewatering. It is mounted in the canal with the angles of 35 degrees, and the wastewater flows into the drum from the port of the drum. The water flows out from the side of the drum, and the grid can intercept the dregs. Then the drum moves at a fixed speed, and the nylon brush and flush water spray nozzle above the drum can get rid of dregs and export them through spiral lifting. Dregs by dewatering and pressing will be delivered to the container or the transportation equipment. The whole process is clear and no smell.

Features

n High efficiency and flowrate

n Full stainless steel made, low maintance, long lifetime

n Equiped with flushing device for self cleaning

n Integrated multi-function, compact structure

Specifications

|

Model (TPR) |

600 |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

|||||

|

Drum diameter(mm) |

600 |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

|||||

|

Drum length (mm) |

650 |

830 |

985 |

1160 |

1370 |

1500 |

1650 |

2000 |

2200 |

2200 |

2400 |

|||||

|

Highest water lv.(mm) |

400 |

500 |

670 |

800 |

930 |

1100 |

1200 |

1300 |

1500 |

1680 |

1800 |

|||||

|

Motor power (kw) |

1.1 |

1.5 |

2.2 |

3 |

||||||||||||

|

Installation angle |

35°/Designed as per request |

|||||||||||||||

|

Channel depth(mm) |

600-3000 |

|||||||||||||||

|

Discharge height |

Designed as per request |

|||||||||||||||

|

Liquid speed (m/s) |

1 |

|||||||||||||||

|

Flowrate (m³/h) |

Screen gap(mm) |

0.5 |

80 |

135 |

240 |

310 |

450 |

585 |

745 |

920 |

1130 |

1380 |

2080 |

|||

|

1 |

125 |

220 |

370 |

510 |

720 |

955 |

1210 |

1495 |

1800 |

2150 |

3280 |

|||||

|

2 |

190 |

330 |

560 |

765 |

1100 |

1440 |

1830 |

2260 |

2730 |

3250 |

4530 |

|||||

|

3 |

230 |

400 |

685 |

935 |

1340 |

1760 |

2235 |

2760 |

3330 |

3970 |

5450 |

|||||

|

4 |

240 |

430 |

720 |

1010 |

1440 |

2050 |

2700 |

3340 |

4030 |

4680 |

6230 |

|||||

|

5 |

250 |

470 |

795 |

1110 |

1570 |

2200 |

2935 |

3600 |

4360 |

5220 |

6750 |

|||||

*Above parameters only for reference, customized available for detailed requirements